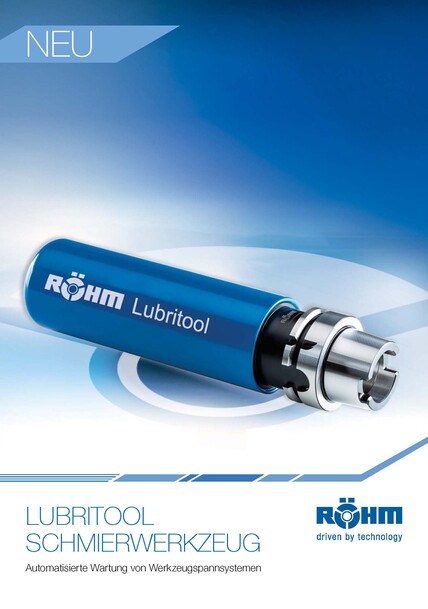

In order to guarantee the impeccable functioning of milling machines and machining centers, the tool clamping system should be lubricated regularly. Lubrication of the clamping set ensures that the tool can always be clamped with constant clamping force for process reliability. The patent-pending Lubritool® lubrication tool enables automatic lubrication within 5 seconds.

So far, manual lubrication has meant a maintenance effort of several minutes. To make all this a thing of the past, RÖHM developed the Lubritool® lubrication tool. After being informed of the correct time by the machine controller, the Lubritool is swapped in automatically directly from the tool magazine and provides the clamping set with the ideal amount of lubrication in just a few seconds.

Operating principle

Lubritool® is located in the tool magazine.Whenever the machine control notifies thata lubrication process is necessary, Lubritool®will be sent up into the spindle.

The lubrication impulse is automatically acti-vated within the spindle. An optimal quantity of Lubriflux lubricant is sprayed onto the right place of the tool clamping system.

After the lubrication process, Lubritool® issent back to the tool magazine and remainsthere until the next lubrication cycle.

[Translate to english:]

1: Schutzhülse für Lubriflux Fettkartusche

2: Optimale Verteilung des Schmiermittels am Spannsatz durch Verteilerring

3: HSK-Aufnahme

Lubritool, HSK

Automatic lubrication for HSK clamping sets; sizes 40, 50, 63, 100

Lubritool, Capto – as of Q2 2020

Automatic lubrication for Capto clamping sets; size C6

Lubritool, KM – as of Q2 2020

Automatic lubrication for KM clamping sets; size 4X63