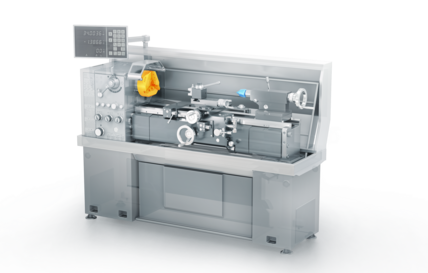

“Sure thing. I turned my first turned parts on a chuck from Röhm eons ago. At that time, it was on a machine that was painted green with a cast iron frame. I have a feeling that lathe chucks from Röhm have been around forever. No wonder, longevity and precision are typical of Röhm. And fortunately, these lathe chucks are still around today. But there is one important difference: Röhm engineers made them a bit better over and over again. More long-lasting. More precise. And lighter. So actually, they are no longer around. But maybe they are. But in the way that you need them today. And they still hold – feels like forever.

The entire Röhm product range, from 2- or 3-jaw jaw chucks up to chucks with individually adjustable jaws, and all the technical data can be found in our online shop.

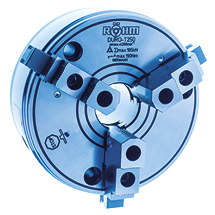

DURO-M – SCROLL CHUCK WITH SPIRAL RING

for variable production with large jaw adjustment range

Key bar chucks with quick jaw change system

for high precision in variable manufacturing with quick changing, turning and offsetting of the jaws.

High-precision geared scroll chucks

for variable manufacturing with a large jaw adjustment range and maximum concentricity

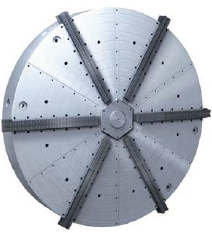

Geared scroll chucks with individual jaw adjustment

for variable manufacturing for adjusting to irregularly-shaped workpieces

Lever scroll chucks

for positioning and conveying workpieces

Jaw cutting attachment

for turning out and grinding out jaws

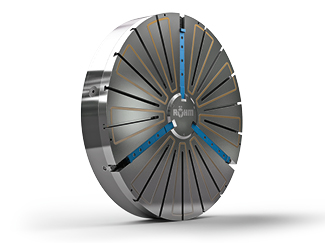

Hybrid chucks with magnetic force

for machining workpieces that are easily deformed

Geared scroll chucks

for variable manufacturing with a large jaw adjustment range

“So you really are from Röhm. You have a really outstanding 3-jaw chuck. We need a minor change. “Couldn’t you...”. Don’t worry, just have the confidence. The engineers at Röhm know that a custom solution is sometimes the better one. And therefore Röhm is the right place for you. With our decades of experience, we will design your individual solution. In the process, we use not only our experience, but also the many products and solutions that have resulted from it. We use these components just like building blocks for the solution to your clamping task.

Talk to our specialists: Contact

Integrated quick-change system for minimum setup times

for machining large bearings and rotary unions.

Centrically clamping wedge hook chuck with quickly adjustable clamping jaws and stops

for minimum setup times for machining large bearings and rotary unions

Clamping diameters of up to 1.3 meters with flexible set-up for individually changing workpiece sizes

for machining for rail traffic

Independent chuck with clamping diameter of up to 5 meters for safe clamping using power spindles for up to 50 tons of clamping force per jaw

for machining for power plants and steel mills

The F-senso 2

For measurement of clamping force on lathe chucks.